#Modular Pump Control Displays

Explore tagged Tumblr posts

Text

Fire Pumps Controls, Fire Pumps Accessories, Manufacturer, India

Manufacturer, Supplier of Fire Pumps Controls, Fire Pumps Accessories, Modular Pump Control Displays, Water And Foam Level Indicators from Kolhapur India.

#Fire Pumps Controls#Pump Controls#Modular Pump Control Displays#Water And Foam Level Indicators#Fire Pumps Accessories#Master Control Units#Water Level Indicator#Foam Level Indicator#RPM And Hour Meters#Pump Accessories#Fire Pumps#Fire Fighting Pumps#Diesel Fire Fighting Pump#Diesel Fire Fighting Pumps#Diesel Fire Pumps#Diesel Portable Fire Fighting Pump#Fire Hawk PTO#Fire Hawk Power Take Off#Power Take Off#Fog Guns#Manufacturer#Supplier#Exporter#Kolhapur India.

0 notes

Text

Best 5 Solar Generators for Home Backup

In an age of rising energy costs and unpredictable weather events, having a solar generator as a home backup is not just smart—it's essential. Whether it’s a short power outage or a prolonged blackout, solar generators provide clean, quiet, and renewable energy to keep your home running smoothly.

But with so many options on the market, how do you choose the right one?

We've done the research so you don’t have to. Here are the 5 best solar generators for home backup in 2025, based on power capacity, reliability, ease of use, and value.

💡 Want a full breakdown with expert reviews, specs, and comparisons? Visit our in-depth guide here: Best Solar Generators for Home Backup

1. EcoFlow Delta Pro

Best for Whole-House Backup

Battery Capacity: 3600Wh (expandable to 25kWh)

AC Output: 3600W (surge 7200W)

Solar Input: 1600W max

Notable Features: Fast charging, EV-level battery chemistry, app control

The EcoFlow Delta Pro is a beast. It’s built to run high-wattage appliances like refrigerators, sump pumps, and even AC units. With expandable battery options, this is the closest thing to a true whole-house backup on solar.

2. Jackery Explorer 2000 Plus

Best for Plug-and-Play Simplicity

Battery Capacity: 2042Wh (expandable)

AC Output: 3000W

Solar Input: 1400W

Notable Features: Modular, lightweight for its size, user-friendly interface

Jackery is a household name in solar power, and the Explorer 2000 Plus continues the tradition. It’s a great choice if you want something powerful yet easy to operate, ideal for running essentials during outages like lights, routers, fans, and medical devices.

3. Bluetti AC200MAX

Best Mid-Range Powerhouse

Battery Capacity: 2048Wh (expandable)

AC Output: 2200W (surge 4800W)

Solar Input: 900W

Notable Features: 16 ports, wireless charging, LiFePO4 battery

The Bluetti AC200MAX hits a sweet spot between affordability and performance. It’s ideal for homes that want reliable power for several hours or even a few days, especially when paired with solar panels for continuous charging.

4. Anker SOLIX F2000 (PowerHouse 767)

Best Compact Solar Generator

Battery Capacity: 2048Wh

AC Output: 2400W

Solar Input: 1000W

Notable Features: Industrial-grade wheels, unibody design, smart display

Anker’s SOLIX F2000 is sleek, durable, and efficient. It’s not just for power outages—it’s also a favorite for weekend camping or powering tools in remote areas. Great mix of portability and power.

5. Geneverse HomePower TWO PRO

Best for Family Emergency Kits

Battery Capacity: 2419Wh

AC Output: 2200W (surge 4400W)

Solar Input: 800W

Notable Features: Indoor-safe, easy touchscreen, silent operation

Formerly known as Generark, Geneverse has quickly become popular for home emergency power. The TWO PRO is quiet, safe to use indoors, and comes ready to go out of the box—perfect for families who want simple, reliable backup.

Final Thoughts

Investing in a solar generator for home backup is no longer just for off-grid enthusiasts. It's a practical, eco-conscious choice for anyone who wants to stay prepared in a changing world.

All five of these generators offer excellent performance and are trusted by thousands of users. Whether you’re looking to power a few critical devices or your entire home, there’s a solar backup solution for you.

✅ For full reviews, spec sheets, and current discounts, check out our guide at AVSolarRanchOne.com.

0 notes

Text

ARM Embedded Controllers ARMxy in Building Fire Protection Systems

Main Application Scenarios

Fire Detection and Alarming: ARM controllers integrate sensors (e.g., smoke, temperature, gas sensors) to monitor environmental data in real-time, using algorithms to assess fire risks and trigger alarms.

Fire Equipment Control: Manage fire pumps, sprinkler systems, fire doors, smoke exhaust fans, etc., ensuring rapid response during a fire.

Communication and Networking: Support multiple communication protocols (e.g., Modbus, CAN, Ethernet, 4G, Wifi) for connectivity with fire control centers, cloud platforms, or other smart devices.

Data Processing and Storage: Process large amounts of sensor data and log events for post-incident analysis and system optimization.

Human-Machine Interaction: Drive displays or touchscreens to provide status monitoring and operation interfaces for fire protection systems.

Emergency Power Management: Manage backup power sources (e.g., UPS or batteries) to ensure system operation during power outages.

Advantages of ARM Embedded Controllers ARMxy series

High Performance and Low Power Consumption: ARM Cortex-M series (e.g., Cortex-M4, M7) or Cortex-A series offer strong computing power while maintaining low energy consumption, ideal for continuous operation in fire systems.

Rich Peripheral Support: ARMxy series Integrated RS485, GPIO, DI, DO, AI, AO. RS232, CAN, RTD, etc., facilitate connections to various sensors and actuators.

Real-Time Capability: Support real-time operating systems (RTOS, e.g., FreeRTOS, uC/OS) to ensure low-latency fire detection and response.

Scalability: ARMxy series supports modular design, enabling easy system upgrades or feature expansions.

Cost-Effectiveness: ARM chips are relatively affordable, suitable for large-scale deployment in building fire systems.

Security: Support encryption modules and secure boot to prevent malicious tampering, ensuring system reliability.

Typical Implementation Cases

Smoke Alarm System: Use ARM Cortex-A7 controllers BL330 with smoke sensors, collecting data via DI/AI to trigger buzzers or networked alarms.

Smart Fire Hydrant Monitoring: ARM controllers monitor hydrant water pressure and status, uploading data to the cloud via Ethernet, 4G or WiFi.

Building Fire System Integration: Cortex-A55 controllers BL410 running Linux integrate video surveillance, fire alarms, and evacuation guidance for comprehensive management.

Development Considerations

Reliability: Fire systems require 24/7 operation; select industrial-grade ARM chips to ensure high temperature resistance and anti-interference.

Redundancy Design: Include backup controllers or communication channels to prevent single-point failures.

Certification Standards: Ensure compliance with fire protection standards.

Power Optimization: Use sleep modes or dynamic frequency scaling to reduce energy consumption and extend device lifespan.

Software Security: Regularly update firmware to mitigate potential cyberattacks.

Summary

ARM embedded controllers, with their high performance, low power consumption, and flexibility, have become core components of building fire protection systems. Through proper chip selection and design, they enable efficient and reliable fire detection, equipment control, and emergency response, significantly enhancing building fire safety.

0 notes

Text

"Innovations in Fountain Manufacturing: From Concept to Creation"

Fountains have long been a symbol of elegance, artistry, and innovation in both public spaces and private landscapes. But behind their beauty lies a complex process that combines creativity, engineering, and cutting-edge technology. Today, fountain manufacturing is evolving faster than ever, thanks to new tools, materials, and design approaches that are transforming how water features are conceptualized, built, and maintained.

In this blog, we’ll explore the latest innovations in fountain manufacturing—tracing the journey from initial concept to fully realized creation—and how these advancements are redefining what’s possible in modern water feature design.

The Evolving World of Fountain Manufacturing

Traditionally, fountain manufacturing relied on manual craftsmanship and standard materials such as stone and bronze. While these elements are still valued, modern projects now incorporate digital design, sustainable materials, and smart systems. This combination allows for more complex, interactive, and efficient fountains that enhance both aesthetics and functionality.

Let’s take a closer look at the innovations shaping the future of fountain manufacturing.

1. Digital Design and 3D Visualization

One of the biggest changes in fountain manufacturing is the use of advanced digital tools. Designers can now create highly detailed 3D models and simulations of a fountain before any physical work begins. These models help stakeholders visualize the final product, identify design flaws early, and test how water, light, and movement will interact.

Software like AutoCAD, Rhino, and Blender allows for rapid prototyping, while virtual reality (VR) provides immersive design reviews, making it easier to communicate ideas with clients and collaborators.

2. Smart Water Control Systems

Fountains today are more than just static displays—they’re interactive, programmable, and responsive. Modern fountain manufacturing often includes smart water management systems that control flow rates, patterns, and lighting sequences in real-time.

Sensors and automation enable fountains to respond to environmental changes, such as adjusting flow during windy conditions or reducing water use during droughts. This not only enhances the visual experience but also improves efficiency and sustainability.

3. Sustainable Materials and Practices

With increasing awareness of environmental impact, sustainability has become a key focus in fountain manufacturing. Innovations include:

Recycled and eco-friendly materials like composite stone and low-carbon concrete.

Closed-loop water systems that minimize water waste and improve filtration.

Energy-efficient pumps and LED lighting that reduce power consumption.

These practices allow manufacturers to create stunning water features without compromising environmental responsibility.

4. Modular and Prefabricated Components

To streamline construction and reduce costs, many manufacturers are turning to modular and prefabricated components. These parts are built off-site and then assembled quickly at the installation location. This method improves quality control, reduces labor time, and minimizes disruption in public spaces.

Prefabrication also enables greater consistency across multiple fountain installations, especially in commercial or franchise settings.

5. Integration with Architecture and Landscape Design

Fountain manufacturing today emphasizes harmony with the surrounding environment. Architects and landscape designers work closely with manufacturers to ensure that fountains enhance the overall aesthetic and functionality of a space.

Whether it’s a centerpiece in an urban plaza, a serene element in a botanical garden, or a dynamic feature in a corporate lobby, the integration of water features with design elements like paving, lighting, and seating is more seamless than ever.

From Concept to Creation: The Process

The journey of a modern fountain typically includes the following steps:

Concept Development – Brainstorming ideas, sketches, and initial designs.

Digital Modeling – Creating 3D visualizations and simulations.

Engineering and Planning – Designing water flow systems, selecting materials, and preparing construction plans.

Fabrication – Producing components using CNC machines, molds, and manual craftsmanship.

Installation – Assembling, plumbing, and testing the fountain on-site.

Programming and Testing – Finalizing lighting, automation, and water sequences.

Each stage is enhanced by innovation, ensuring better outcomes, faster delivery, and greater creative possibilities.

Conclusion

Fountain manufacturing has come a long way from its classical roots. Today, it’s a sophisticated blend of technology, sustainability, and artistic vision. Innovations in digital design, smart systems, eco-conscious materials, and modular construction are making it easier than ever to bring ambitious fountain concepts to life.

As these technologies continue to evolve, we can expect even more immersive, interactive, and awe-inspiring fountains in the future—proving that the fusion of water, art, and innovation is as timeless as it is transformative.

0 notes

Text

Using Pipetting Robots: Enhancing Laboratory Efficiency

Contemporary laboratories are under continuous pressure to provide precise results faster, more efficiently, and with fewer human errors. With the advancement of technology, one of the strongest innovations that increases lab productivity is the robot micropipette.

These automated platforms have transformed liquid manipulation for laboratory technicians and scientists with uniformity, efficiency, and reduced fatigue. But what makes pipetting robots so revolutionary in laboratories?

Let us examine the overall use of automated liquid handling instruments and how pipetting robots are improving efficiency in research, diagnostics, pharmaceuticals, and beyond.

What are Pipetting Robots?

Liquid handling robots, also known as pipetting robots, are machines that perform tasks that were previously done manually with the help of pipettes. Pipetting robots have precision mechanisms and software that allow them to add and remove liquids between different samples or containers with great accuracy.

They find application from the extraction of DNA/RNA to drug discovery's high-throughput screening, not only hastening the process but also standardising every step.

Increased Accuracy and Precision

One of the key benefits of pipetting robots is precision. Unlike manual pipetting, whose range of variation is reliant on the expertise and stability of the user, robotic pipetting is controlled by sensors and computer software, which provide precise volumes each time. This removes cross-contamination and human error, both major problems in sensitive experiments, quite considerably.

Increased Throughput

Speed is of the essence in most laboratories. Pipetting robots handle dozens or hundreds of samples in a single pass without interruption and are therefore well-placed for high-throughput applications. This greatly accelerates the rate of experiments and enables scientists to concentrate on interpreting data and analysis rather than monotonous manual work.

Integration with Liquid Handling Instruments

The capacity of pipetting robots is doubled when combined with other liquid handling instruments. These include reservoirs, mixers, and dispensers, which combine with robotic systems to fully automate entire workflows.

Regardless of whether a 96-well PCR plate or serial dilutions are being prepared, the built-in design ensures precision and efficiency in every step.

Most advanced pipetting robots are designed in modular form, hence they can be tailored to fit the individual needs of experiments.

Transition from Manual to Electronic Devices

Even though traditional micropipettes have been a lab standard for decades, they are increasingly being replaced by more intelligent, ergonomic pipettes. The shift from electronic to manual pipettes is a trend driven by requirements for compatibility, convenience, and consistency.

One of the most important advances in the area is the electronic pipette pump. These pumps mechanise aspiration and dispensing through motorised motion, reducing user fatigue and enhancing the precision of pipetting.

They are particularly valuable in repetitive processes or the handling of volatile chemicals or thixotropic chemicals, where high control is necessary.

How do Electronic Pipettes Complete Automation?

An electronic pipette provides a compromise between manual pipetting and full automation systems. They are best for laboratories that are not yet ready to invest in complete robotic systems but require greater accuracy and convenience.

Electronic pipettes will also have programmable parameters, memory functions, and digital displays, making them significantly more convenient to use than manual ones. They also support semi-automatic installations, which are flexible enough to cater to changing lab needs.

Where robotic pipetting is not yet feasible, due to cost, space, or space considerations. Electronic pipettes offer a compelling alternative for better performance and precision.

Titration Specific Equipment: Welcome to the E-Burette

Accumulation and control are required for titration experiments. That is where the e-burette comes in. While mechanical glass burettes are operated by a manual interface, e-burettes provide direct digital control over titrant flow, improving repeatability as well as constraining parallax error.

Such e-burettes are generally accompanied by data analysis software programs that provide immediate monitoring and recording of the data, enabling scientists to keep safe and reliable records of volume dispensed, flow rate, and endpoint detection.

Coupled with pipetting robots or electronic pipettes, e-burettes maximise complex workflows, best suited for pharma, analytical chem labs, and university research.

Benefits of Pipetting Robots

The following are the primary advantages that pipetting robots provide to laboratories:

Consistency: Collect and prepare sample preparation for multiple experiments. This will be useful and time-saving through your experiments.

Time-Saving: Saving time is the goal. Automation in the laboratory can enable laboratories to process more samples in a given period, without causing any delay.

Cost-Effectiveness: In a laboratory, the initial cost of acquisition may be high, but pipetting robots save pennies on reagents, mistakes, and labour costs in the long term.

Data Integration: High-end systems can be integrated with Laboratory Information Management Systems (LIMS) to provide real-time tracking and reporting of data.

Scalability: From a small research institution to a big pharma company, pipetting robots can be scaled up or down to fit your operations. As they can be supported due to their enhanced versatility.

Real-World Applications of Pipetting Robots

Let's look at some actual application areas where pipetting robots are contributing:

Genomics: Automation of sample preparation for next-gen sequencing. This can be helpful for speeding up the experimentation process.

Drug Discovery: Screening compound libraries by high-throughput screening. Robotics can focus on minute details that may have been missed through the microscope lens in the laboratory.

Diagnostics: Processing hundreds of patient samples daily with minimal error. It will also streamline the experiment and keep the results up to date.

Food and Beverages: Testing for quality in manufacturing plants, food and beverages need constant scrutiny throughout their manufacturing. Robotic interference may keep the edibles in check by maintaining their quality.

Environmental Science: Scaled testing of water and soil samples will improve the overall environmental quality. This will also enhance the scientific environmental standards with precise measurements.

Selecting the Right System for Your Laboratory

When you select a pipetting robot or companion device for your laboratory, think about:

Range of Volume: In a laboratory, which volume do you handle most frequently throughout the experiment?

Throughout Requirements: This depends on the number of experiments you are conducting in a day. For which you need external support for enhancing the process.

Ability to Integrate: Will the robot have to be interfaced to other lab instruments or computer software?

User Interface: Is the system easy to use for your staff?

Budget: What are the purchase price and recurring costs, such as maintenance, consumables, etc.?

Lab instrument companies like Microlit will typically offer demo models and service with reconfiguring of the system to your specific needs.

The Future of Laboratory Automation

As advances in robotics and artificial intelligence continue, pipetting robots will become smart, with needs foreseen, aberrant behaviours detected, and self-optimal performance offered. Through historical data read using machine learning algorithms, future equipment might even predict experimental outcomes or propose process optimisation.

Besides, cloud integration will ensure remote monitoring, as sample progression will be posted in real time from anywhere in the world. With green features like smart reagent management, laboratories in the future will be quicker, greener, and more accurate than they are today.

Conclusion

In the high-speed research and diagnostic settings of today, accuracy and speed are not negotiable. Pipetting robots and associated equipment like micropipettes, electronic pipette pumps, and e-burettes are at the forefront of revolutionising laboratory workflows.

Whether you’re stepping into automation with a reliable electronic pipette or investing in a full-fledged robotic liquid handling system, the benefits are clear: fewer errors, faster results, and better science. With automation becoming the rule rather than the exception, now is the ideal time for labs to get on board, one accurate drop at a time. Are you a laboratory looking to elevate your experiment standards? Contact Microlit today and move towards more efficient experimenting.

#micropipette#Pipetting#liquid handling#pipettes#liquid handling instruments#electronic pipette pump#e-burettes#electronic pipette

0 notes

Text

What Is Firmware Development?

In today’s increasingly connected world, embedded systems power everything from smart home devices to medical equipment and automotive technology. At the heart of these systems lies firmware development—a specialized field that ensures devices run smoothly, efficiently, and securely. If you're building any smart or electronic product, understanding firmware and investing in expert firmware development is key to delivering performance, reliability, and innovation.

What Is Firmware?

Firmware is a type of software that provides low-level control over a device's hardware. Unlike traditional software applications, firmware resides in the device’s memory (often in ROM, flash, or EEPROM) and interfaces directly with the hardware components.

Firmware is what tells a device how to operate, boot, and respond to external commands. It’s typically involved in controlling:

Microcontrollers (MCUs)

Sensors

Actuators

Display modules

Communication modules (e.g., Wi-Fi, Bluetooth)

Because of its vital role, firmware development is an essential part of the embedded systems lifecycle.

What Is Firmware Development?

Firmware development is the process of designing, programming, testing, and maintaining the firmware that controls electronic hardware. Developers work at the intersection of hardware and software, writing code that interacts directly with microprocessors and chipsets.

This type of development typically involves:

Selecting the right microcontroller or system-on-chip (SoC)

Programming in low-level languages like C, C++, or Assembly

Interfacing with hardware peripherals

Real-time operating system (RTOS) integration

Debugging and testing using tools like JTAG, oscilloscopes, or logic analyzers

Updating and maintaining firmware post-deployment

Well-executed firmware development ensures that devices are not only functional, but also stable, efficient, and secure.

Why Firmware Development Is Crucial

In a world driven by smart technology, firmware development plays a critical role in the success of a product. Here’s why:

1. Optimized Performance

Firmware directly controls hardware operations. Efficient firmware code leads to faster processing, lower power consumption, and improved user experience.

2. Hardware Integration

Firmware allows software and hardware to communicate seamlessly. Whether it’s a smart thermostat or a medical device, firmware development ensures that components such as sensors, motors, and displays function correctly.

3. Product Reliability

Poorly written firmware can result in device malfunctions, crashes, or safety issues. Reliable firmware ensures devices perform predictably under various conditions.

4. Security

Many cyberattacks target firmware vulnerabilities. Secure firmware development practices, including encryption and authentication, are essential to protect devices and user data.

5. Upgradability

Modern devices often require firmware updates to fix bugs or add features. Proper firmware development includes designing systems that support over-the-air (OTA) updates without bricking the device.

Industries That Rely on Firmware Development

The demand for skilled firmware development is booming across various sectors:

Consumer electronics (smartphones, smart TVs, wearables)

Automotive (ADAS, electric vehicles, infotainment systems)

Industrial automation (IoT sensors, PLCs, robotics)

Healthcare (wearable monitors, infusion pumps, diagnostic devices)

Telecommunications (network hardware, routers, modems)

Aerospace and defense (navigation systems, avionics)

Whether it’s a smartwatch or a life-saving medical device, firmware is often the unseen hero behind the scenes.

Best Practices in Firmware Development

To ensure a successful project, firmware developers follow a structured approach:

Clear hardware documentation: Understand the chipset’s datasheets and schematics before writing code.

Modular design: Create reusable and maintainable code blocks.

Version control: Use Git or SVN to track changes and collaborate efficiently.

Automated testing: Implement unit tests and simulation environments to catch bugs early.

Debugging tools: Use debuggers and analyzers to test real-world behavior.

Code optimization: Ensure the code is fast, power-efficient, and small in memory footprint.

Partnering with experienced firmware developers is essential to bring a hardware product to life without delays or technical setbacks.

The Future of Firmware Development

As more industries adopt IoT, artificial intelligence, and edge computing, firmware development is becoming even more critical. We’re seeing trends like:

AI-powered firmware for smart decision-making

Increased emphasis on security and firmware-level encryption

Remote firmware updates through cloud platforms

Low-power firmware for battery-dependent IoT devices

Staying on top of these trends can give your business a competitive advantage in delivering cutting-edge, reliable technology.

Conclusion

Firmware development is the backbone of modern electronics, enabling smart devices to operate safely, efficiently, and intelligently. From prototyping to production and post-launch updates, investing in expert firmware development is crucial for any business building connected hardware.

Whether you're launching a new product or improving an existing one, working with skilled firmware developers can save time, reduce costs, and ensure your technology stands out in a crowded market.

0 notes

Text

What Is Firmware Development?

In today’s increasingly connected world, embedded systems power everything from smart home devices to medical equipment and automotive technology. At the heart of these systems lies firmware development—a specialized field that ensures devices run smoothly, efficiently, and securely. If you're building any smart or electronic product, understanding firmware and investing in expert firmware development is key to delivering performance, reliability, and innovation.

What Is Firmware?

Firmware is a type of software that provides low-level control over a device's hardware. Unlike traditional software applications, firmware resides in the device’s memory (often in ROM, flash, or EEPROM) and interfaces directly with the hardware components.

Firmware is what tells a device how to operate, boot, and respond to external commands. It’s typically involved in controlling:

Microcontrollers (MCUs)

Sensors

Actuators

Display modules

Communication modules (e.g., Wi-Fi, Bluetooth)

Because of its vital role, firmware development is an essential part of the embedded systems lifecycle.

What Is Firmware Development?

Firmware development is the process of designing, programming, testing, and maintaining the firmware that controls electronic hardware. Developers work at the intersection of hardware and software, writing code that interacts directly with microprocessors and chipsets.

This type of development typically involves:

Selecting the right microcontroller or system-on-chip (SoC)

Programming in low-level languages like C, C++, or Assembly

Interfacing with hardware peripherals

Real-time operating system (RTOS) integration

Debugging and testing using tools like JTAG, oscilloscopes, or logic analyzers

Updating and maintaining firmware post-deployment

Well-executed firmware development ensures that devices are not only functional, but also stable, efficient, and secure.

Why Firmware Development Is Crucial

In a world driven by smart technology, firmware development plays a critical role in the success of a product. Here’s why:

1. Optimized Performance

Firmware directly controls hardware operations. Efficient firmware code leads to faster processing, lower power consumption, and improved user experience.

2. Hardware Integration

Firmware allows software and hardware to communicate seamlessly. Whether it’s a smart thermostat or a medical device, firmware development ensures that components such as sensors, motors, and displays function correctly.

3. Product Reliability

Poorly written firmware can result in device malfunctions, crashes, or safety issues. Reliable firmware ensures devices perform predictably under various conditions.

4. Security

Many cyberattacks target firmware vulnerabilities. Secure firmware development practices, including encryption and authentication, are essential to protect devices and user data.

5. Upgradability

Modern devices often require firmware updates to fix bugs or add features. Proper firmware development includes designing systems that support over-the-air (OTA) updates without bricking the device.

Industries That Rely on Firmware Development

The demand for skilled firmware development is booming across various sectors:

Consumer electronics (smartphones, smart TVs, wearables)

Automotive (ADAS, electric vehicles, infotainment systems)

Industrial automation (IoT sensors, PLCs, robotics)

Healthcare (wearable monitors, infusion pumps, diagnostic devices)

Telecommunications (network hardware, routers, modems)

Aerospace and defense (navigation systems, avionics)

Whether it’s a smartwatch or a life-saving medical device, firmware is often the unseen hero behind the scenes.

Best Practices in Firmware Development

To ensure a successful project, firmware developers follow a structured approach:

Clear hardware documentation: Understand the chipset’s datasheets and schematics before writing code.

Modular design: Create reusable and maintainable code blocks.

Version control: Use Git or SVN to track changes and collaborate efficiently.

Automated testing: Implement unit tests and simulation environments to catch bugs early.

Debugging tools: Use debuggers and analyzers to test real-world behavior.

Code optimization: Ensure the code is fast, power-efficient, and small in memory footprint.

Partnering with experienced firmware developers is essential to bring a hardware product to life without delays or technical setbacks.

The Future of Firmware Development

As more industries adopt IoT, artificial intelligence, and edge computing, firmware development is becoming even more critical. We’re seeing trends like:

AI-powered firmware for smart decision-making

Increased emphasis on security and firmware-level encryption

Remote firmware updates through cloud platforms

Low-power firmware for battery-dependent IoT devices

Staying on top of these trends can give your business a competitive advantage in delivering cutting-edge, reliable technology.

Conclusion

Firmware development is the backbone of modern electronics, enabling smart devices to operate safely, efficiently, and intelligently. From prototyping to production and post-launch updates, investing in expert firmware development is crucial for any business building connected hardware.

Whether you're launching a new product or improving an existing one, working with skilled firmware developers can save time, reduce costs, and ensure your technology stands out in a crowded market.

0 notes

Text

Some key features and applications of diode laser module

Diode laser module are integrated devices that combine the laser diode with driving circuits, cooling systems, and optical components. They are widely used in various industries, medical applications, and research fields. Here are some key features and applications of diode laser module:

Technical Specifications: For instance, a 650nm wavelength laser diode has an output power of 5mW, operating voltage between 2.2 and 2.7V, threshold current ranging from 15mA to 30mA, and operating current of 65 to 80mA. Beam divergence angles are typically between 8 to 12 degrees for the parallel direction and 23 to 32 degrees for the perpendicular direction.

Low Noise Modules: Ultra Low Noise (ULN) diode laser module are designed for applications that require exceptionally low noise or noise-free operation without mode-hops. These modules use sophisticated drive electronics to ensure low noise output, with typical root mean square (RMS) noise of 0.06% or better.

Wavelength Stabilized Modules: SureLock diode laser module offer superior optical stability, making them ideal for applications such as Raman spectroscopy and metrology. They are available across a wide range of wavelengths, power levels, and form factors.

High-Power Lasers: High-power diode laser designs are advancing in industrial processing applications, including cutting, welding, and foil joining of copper and other highly reflective materials. Blue diode laser designs are particularly making strides in these applications.

Modular Solutions: Companies like Nuburu have taken a different approach by mounting Osram's GaN single-emitter diodes on a chip in series, which reduces operating current and enables responsive control of power and pulse modes. This modular architecture allows for scaling up to multi-kilowatt lasers using spatial and polarization combiners.

Applications: diode laser module are used in precision pointing and alignment of optical elements, printing and imaging systems, displays, barcode scanning, optical data storage, optical sensors, pumping of solid-state lasers, free-space optical communications, and medical applications (such as photodynamic therapy, ophthalmology).

High Brightness Modules: High brightness fiber-coupled single emitter laser diodes and their assessment under various harsh conditions are provided by modules like the Ultra Compact Hermetic (UCH) modules. These modules deliver up to 10W out of the fiber at 25°C and more than 8W at 60°C for λ=940nm.

Fiber-Coupled Modules: The ST Series fiber-coupled diode pump module offers up to 140W output through a 106.5 μm fiber. It uses a high-power proprietary chip optimized for reliability at high peak power, leveraging a long history of fiber-coupled packages for a scalable and reliable commercial product.

These diode laser module typically offer more user-friendly operation than bare laser diodes, incorporating functions such as beam shaping, power and wavelength stabilization, power modulation, pulse generation, wavelength conversion, electrical connections, cooling, and temperature stabilization.

0 notes

Text

How SINAMICS G120 Drives Enhance Energy Efficiency in Industrial Applications?

It is a modular drive system from Siemens that has been used widely in different industries, having made its way into people’s minds reluctantly. The SINAMICS G120 is a remarkably strong and multifunctional device. The author would elaborate on this subject through this post.

What is the SINAMICS G120?

Designed for use in a variety of industrial applications, the SINAMICS G120 is a modular, general-purpose drive system. It is one of the SINAMICS collections from Siemens which are reputed for their functionality, versatility and ease to integrate. Particularly applications that need accuracy and power saving consider this type of drive because it can be used on simple conveyer belts as well as sophisticated production systems.

Key Features of the SINAMICS G120

Modular Design: The modularity of the SINAMICS G120 Drive is one of its most outstanding features. The drive system consists of three main components:

Power Module (PM): It takes the incoming AC voltage which is then converted into DC followed by a variable AC output for motor control.

Control Unit (CU): Controls the motor and interface of the other automated systems.

Optional Modules: such as Communication modules, input filters, braking resistors, etc.

This kind of modularity ensures that systems can be customized for individual applications while offering flexible ways to configure them, make upgrades, and perform maintenance work.

Safety Integration: Industrial measures have placed safety at the very beginning of their priority lists, hence G120 Power Module has it all including built-in safety functions. Like in any system but example given here is purely indicative – Safe Torque Off (STO), Safe Stop 1(SS1) & Safe Brake Control (SBC); these functions enable proper and sure cut-off of the motor during emergencies. These precautions meet global standards therefore giving us assurance during vulnerable situations.

Energy Efficiency: The SINAMICS G120 is designed to keep energy efficiency in focus. Some of its features include regenerative feedback where energy is returned back to supply during braking and eco mode which optimizes drive power consumption according to the loading conditions. Thus, these features will not only lower operational costs, but they also contribute towards a reduced carbon footprint.

Versatile Communication Options: In contemporary industrial surroundings that are connected to each other, smooth communication among devices is very important. The Drive G120 accepts diverse communication protocols such as PROFINET, PROFIBUS, EtherNet/IP, and Modbus. This feature enables it to fit into any automation system seamlessly despite different standards of communication being utilized.

User-Friendly Interface: The SINAMICS G120 has an advantage of use. It comes equipped with a Basic Operator Panel (BOP) or an Intelligent Operator Panel (IOP) depending on how it is configured. These panels have a clear display and intuitive operation which makes the setup process, monitoring and troubleshooting simple. Moreover, robust tools for configuration and parameterization are provided by the STARTER commissioning software as well as by SINAMICS Startdrive tool within the TIA Portal.

Applications of SINAMICS G120

The SINAMICS G120’s high degree of flexibility qualifies it for numerous applications like:

Pumps and Fans: The G120 enhances the operation of pumps and fans by means of accurate speed regulation thereby minimizing energy usage while prolonging the lifespan of equipment.

Conveyors: In the field of manufacturing processes and material transportation within an area, G120 always guarantees seamless and effective running despite changes that happen to weights involved.

Mixers and Agitators: Since it can cope with fluctuating velocities and torques, this is also why it is best suited for organizations that use it in food and beverage production, chemicals industry, as well as those engaged in the manufacture of pharmaceuticals.

Compressors: The SINAMICS G120 is a dependable and energy-saving regulator for applications where constant pressure and flow are vital.

Why Choose SINAMICS G120?

For its blend of effectiveness, versatility and simplicity, the G120 Power Module is something to be reckoned with. With its modular design, it can easily be configured for specific applications; the built-in safety features and power efficiency make it a wise solution for organizations that want to improve their processes. In addition, there are multiple pathways for communication so that it fits effortlessly into an automated setting.

Conclusion

To sum up, the Drive G120 is not simply a drive; it is an adaptable, dependable and effective answer for a variety of industrial uses. The SINAMICS G120 is an incredibly powerful device that can be used to achieve energy efficiency improvements, increase safety or provide accurate and smooth control of your processes.

Investing in the SINAMICS G120 means investing in a system that can adapt continuously to the changing requirements of your company and thus providing you with performance and reliability necessary for staying ahead in the highly competitive arena of industrial automation.

0 notes

Text

In the ever-evolving world of industrial automation, efficient motor control and energy management are crucial for enhancing productivity and reducing operational costs. This is where Danfoss Drives come into play, providing state-of-the-art solutions for a variety of applications. At Adhunik Automation India, we recognize the importance of integrating cutting-edge technology to optimize industrial processes, and Danfoss Drives are a testament to our commitment to excellence.

What are Danfoss Drives?

Danfoss Drives are advanced electronic devices used to control the speed, torque, and direction of electric motors. They are part of the broader category known as Variable Frequency Drives (VFDs), which regulate the power supplied to motors, allowing them to operate at optimal efficiency. By adjusting the motor speed to match the requirements of the application, Danfoss Drives help in reducing energy consumption, minimizing wear and tear, and extending the lifespan of the equipment.

Why Choose Danfoss Drives?

At Adhunik Automation India, we understand the diverse needs of our clients across various industries. Danfoss Drives stand out due to their reliability, efficiency, and versatility. Here are some reasons why Danfoss Drives are the preferred choice for many industries:

Energy Efficiency: Danfoss Drives are designed to optimize energy usage, leading to significant cost savings. By adjusting the motor speed based on demand, these drives can reduce energy consumption by up to 50%, making them an eco-friendly and cost-effective solution.

Enhanced Performance: With precise motor control, Danfoss Drives ensure that machines operate smoothly, reducing the risk of mechanical stress and extending the lifespan of equipment. This leads to less downtime and higher productivity, which are critical for industrial operations.

Scalability and Flexibility: Danfoss Drives are suitable for a wide range of applications, from small pumps and fans to large compressors and conveyors. Their modular design allows for easy scalability, enabling businesses to adapt to changing demands without extensive reconfiguration.

User-Friendly Interface: The intuitive interface of Danfoss Drives makes them easy to set up and operate. With advanced diagnostic tools and easy-to-read displays, operators can monitor performance and troubleshoot issues quickly, reducing maintenance time and costs.

Robust Design: Built to withstand harsh industrial environments, Danfoss Drives are known for their durability and reliability. They are equipped with protective features such as over-voltage, over-current, and short-circuit protection, ensuring safe and uninterrupted operation.

Applications of Danfoss Drives

Danfoss Drives are versatile and find applications in a wide range of industries. At Adhunik Automation India, we cater to various sectors, including:

Manufacturing: In manufacturing, Danfoss Drives are used to control conveyor belts, pumps, and fans, optimizing production lines for efficiency and precision.

HVAC Systems: Heating, Ventilation, and Air Conditioning systems benefit from Danfoss Drives by maintaining optimal air flow and temperature control, leading to energy savings and enhanced comfort.

Water and Wastewater Treatment: Danfoss Drives ensure efficient operation of pumps and blowers in water treatment facilities, contributing to water conservation and reducing energy costs.

Food and Beverage: In the food and beverage industry, Danfoss Drives help maintain consistent product quality by precisely controlling mixing, cooling, and packaging processes.

Renewable Energy: Danfoss Drives play a crucial role in wind and solar power generation, optimizing the performance of turbines and inverters for maximum energy output.

Partnering with Adhunik Automation India

As a trusted partner, Adhunik Automation India is committed to providing innovative solutions that meet the unique needs of our clients. By integrating Danfoss Drives into your operations, we can help you achieve greater efficiency, reduce energy consumption, and enhance overall productivity. Our team of experts is dedicated to providing comprehensive support, from installation and configuration to maintenance and troubleshooting.

Conclusion

Danfoss Drives represent a significant advancement in motor control technology, offering a range of benefits that contribute to the efficiency and sustainability of industrial processes. At Adhunik Automation India, we are proud to offer these state-of-the-art solutions to our clients, helping them stay competitive in an ever-changing market. If you are looking to optimize your operations and reduce energy costs, consider the reliability and performance of Danfoss Drives. Partner with us and take the first step towards a more efficient and sustainable future.

0 notes

Text

Rotary Claw Vacuum Pump

5 HP DUPLEX CLAW SPACE SAVER

Features And Benefits

High efficiency, oil-less, contactless, multiclaw technology by Busch - Durable, proven technology, low maintenance, ideal for WAGD applications

Fully compliant with the latest NFPA 99 standards

Easy installation and certification

HMI display - Accurate performance information, touch screen control, complete service data

UL listed NEMA 12 control panel - Safe, reliable, easy to service or troubleshoot

Variable Frequency Drive (VFD) available

Reduced energy costs, consistent vacuum level, reduced noise and heat, longer machine life

No lubrication or sealing fluid required inside the vacuum chamber

Reduced maintenance costs

Low maintenance - simple filter changes, reduced costs

Compact design with single point connection (SPC) or modular configurations

Easy installation, equipment arrangement flexibility

REQUEST A QUOTE

CONTACT US Corporate Office Charlotte, NC 4610 Entrance Drive Suite H, Charlotte, NC 28273. Tel : 704-529-5442 Fax : 704-525-5148 Read More

#dental air compressors#rotary claw vacuum pump#medical gas outlets#oil less vacuum pump#lubricated rotary vane vacuum pump#lab vacuum pump#medical gas manifolds#medical air compressor#medical vacuum pump

0 notes

Text

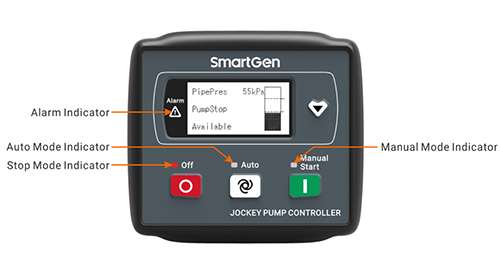

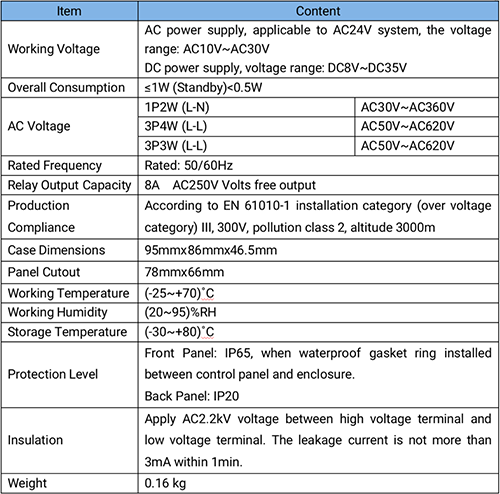

SmartGen | FPC1700 Jockey Pump Controller will launch

FPC1700 Jockey Pump Controller is composed of a microprocessor as the core, which can be started/stopped according to the pipe pressure, stabilize the pipe pressure in the setting range and detect the grid voltage to protect the abnormal voltage, realizing the automation and intelligent control of the controller. It integrates LCD display and with good HMI function.

Characteristics and Performance

1P2W, 3P3W and 3P4W system types are configurable; The LCD is 128x64 pixels with backlight, optional Chinese and English; With MCU smart accurate monitoring and control; With OFF/Auto/Manual modes; With over/under voltage, over/under frequency and reverse phase detection functions, over/under voltage and frequency threshold values are available to set; The cut-in/cut-off pressure threshold values can be set; The pipe pressure sensor can be configured to resistance/current/voltage types, and can customize the sensor curves; LCD can visually display the current pipe pressure, total running time, pump start times, AC power status and alarm status; All the output ports are relay output; Working temperature range is (-25℃~+70℃), which can be used in the bad environments; Rubber seal designed between the enclosure and controller with protection level IP65; Modular design, anti-flaming ABS enclosure, pluggable terminals and built-in mounting with compact structure and easy installation.

FPC1700 Front Panel

FPC1700 Back Panel

Specification Parameters

Please contact business managers of SmartGen for more details, looking forward to your choice! SmartGen, making control smarter!

www.smartgen.cn

0 notes

Text

Fire Pumps Controls, Fire Pumps Accessories, Manufacturer, India

We are Manufacturer, Supplier of Fire Pumps Controls, Fire Pumps Accessories, Modular Pump Control Displays, Water And Foam Level Indicators from Kolhapur India.

Fire Pumps Controls, Pump Controls, Modular Pump Control Displays, Water And Foam Level Indicators, Fire Pumps Accessories, Master Control Units, Water Level Indicator, Foam Level Indicator, RPM And Hour Meters, Pump Accessories, Fire Pumps, Fire Fighting Pumps, Diesel Fire Fighting Pump, Diesel Fire Fighting Pumps, Diesel Fire Pumps, Diesel Portable Fire Fighting Pump, Fire Hawk PTO, Fire Hawk Power Take Off, Power Take Off, Fog Guns, Manufacturer, Supplier, Exporter, Kolhapur, Maharashtra, India.

0 notes

Text

That isn't a ship, it's a cannon with FTL! Pt. 2

The blood red emergency lights gave the USSN PMAC a gory pall, fitting for the literal disembowelment it was preparing for. Navigator Elizabeth Harris’s HUD was a tangle of tracking displays, the ships sensors working overtime to try and keep track of the swarm of ships converging on her position.

The pirates had learned their lesson last time. Big capital ships were what the PMAC specialized in hunting, it’s massive cannon struggling to fire more than once per minute as soon as its capacitor bank was depleted. This swarm of light fighters was far, far more than the ship’s main gun was capable of taking out. Her Plan A solution to this problem was to always maintain an FTL corridor for escape. When she fell for the bait beacon in the Attican nebula, she’d lost that option. Now, she only had Plan B.

Her HUD swapped from white blips of the ships incoming to the red emergency warnings of a power cascade. Voltage from the reactor had tripped the breakers for the sensor array, dumping the excess power into an already overloaded system, causing a chain reaction. The dots on the HUD froze in place as the scanners went offline before the display itself went black, the power bleed pushing its way through the non-essential systems.

“HUDs down!” she yelled over the alarms blaring through the cabin, “I don’t care what you have to do, get it back online! I can’t fly this bitch blind!”

“The only system we can divert power to is artificial-grav !” Thom Pratchett hollered back, “If we do that, nobody but you will stay conscious!”

“I can do it myself, divert power!”

There was the briefest of pauses where Elizabeth could tell that he was considering ignoring her. It was an insane request, he had no idea what her plan was, and she had no time to explain. He had to trust her.

And he did.

Elizabeth could feel the skin in her cheeks sag down dramatically as the environment in the cabin rose from one G to seventeen over the course of less than a second. The augmentations that she’d received from her time as a dogfighter kicked in immediately, her limbs going numb as they constricted their own blood flow to try and force more blood to her brain. As the G meter climbed past ten, the secondary set of augments kicked in, an implanted mechanical pump kicking itself on to try and overcome the massive forces needed to move her blood away from her feet.

The Pratchetts went out like candles. Dalton was struggling to hold on and wouldn’t last more than another minute, but he wasn’t out of the fight yet. Elizabeth wasn’t exactly thrilled about the current situation, but her augments were from the 90-90 batch, ninety seconds of 90 G’s before the pilot risked going unconscious.

Her HUD flickered back on, the swarm moving in alarmingly close in the short seconds that it had been off. Her attention was split between distance counts for the wave of ships coming in, and the warnings that the reactor was reaching dangerous pressure levels.

As the reactor finally hit the redline zone, she hit the emergency disconnect on its modular section. A series of small explosions ripped across the back of the PMAC as the reactor’s bulkhead cut itself out of the ship like a caesarean birth. Inside the ship, most of the alarms stopped as the source of the power cascade was removed from the grid. Weaponsmaster Dalton’s perpetually squared shoulders cubed in relief as the gravity returned to earth standard. The capacitor relay, intended for the gun, was now being used to power the ship.

But that was only part one of the plan.

With the alarms down, there was no need to yell, but Elizabeth’s voice didn’t carry any less urgency for its quiet tone.

“Dalton, you are not rated for the g-forces I’m about to pull in this thing, I need you to give me control of the cannon.”

No pause this time. Dalton was trained for this kind of faith, a blessing of his combat service. As soon as she finished the order, he was already transferring control of the cannon to her. Still, his faith didn’t seem to keep his mouth from running.

“Alright mam, but you get her home by 7 PM sharp, she’ll be yours for the day but don’t you forget who her daddy is.”

Even in the tension of the situation, Elizabeth couldn’t help the derisive snort that escaped her nostrils.

“Damnit Dalton, I am really looking forward to you being unconscious.”

---

Aggral Thrawn was watching his sensors carefully. By all tactical accounts, he should be in the clear, but the behemoth his fighters were circling in on hadn’t delivered its final shots yet. They wouldn’t be enough to stop the swarm, and four light fighters, no matter how gratuitously they were destroyed, were acceptable losses for the defeat of a symbol this large, but it was still peculiar to him. They were waiting for something, but he couldn’t fathom what.

His visual connection showed a series of explosions rip its way up the spine of the ship. He went to hit the comms, demand that whoever was shooting hold their fire, but the com-line was already abuzz with pilots asking each other the same. All of them were insisting that they hadn’t so much as looked at the trigger yet. He swapped to the EM readings, and he was even more baffled by what he saw. The fields on the intact bulkhead drifting off were unmistakable, they could only have jettisoned their own reactor, but he couldn’t even begin to guess why. Such a move had left them as sitting ducks. All he had to do to get a bloodless victory was wait for the capacitor bank in the craft to bleed itself out. It was even better than he’d hoped. He’d been promised by the bloodpact that he could keep every vessel committed to this engagement as his own, provided that it survived the fight. This wasn’t just turning into an acceptable level of loss, it was a perfect victory. He wondered if they’d jumped to the beacon at the cost of cooking their heat loss systems. Why else would they do something so stupid?

---

The white dots had been in range for at least three seconds now, but she’d wanted to play it safe. It wasn’t like she’d get a second shot at this.

In one smooth motion, Elizabeth Harris disengaged the Alcubierre drive, unanchoring the craft from its space coordinates, and slammed the fire command, bypassing the warnings that the recoil management systems were offline. As the 20 kilo ferroslug accelerated up to 0.8 C in the space of 2 microseconds, the PMAC blasted itself backwards at close to 130 G of acceleration.

Dalton joined the Pratchetts in blissful unconsciousness. Elizabeth wondered what this kind of acceleration would do to the man. It was better than being spaced by the pirates, but that wasn’t a high bar to meet.

She hit the fire button once more as the craft began to slow, bringing acceleration up to 200 G. She was almost double the rating of her augments and it was beginning to show. Her diaphragm had no way to overcome that much force, and the pressure of being pushed back into her seat had squeezed every possible bit of air from her lungs. The targeting computer responded to her voice commands, and she prayed that it would be able to read her lips as she desperately mouthed target thermal mass one, target thermal mass one.

Even as she struggled to keep the blackness at the edge of her vision from obscuring the HUD, she could see red flashes as capillaries in the back of her eye exploded like fireworks. Everything but her head had gone completely numb, her augments trying to tourniquet everything below the neck in a desperate bid to buy her a few more seconds of consciousness. Finally, the targeting computer indicated that it had achieved a lock on. As she struggled to reach the fire button through the impossible pressure, she felt the harsh shock of the j-receptor override shoot down her spine. Her arm jerked forward like a rifle shot, muscles and tendons sheering audibly as her body ruined the limb to accomplish its goal. Even through the numbness, she could feel the pain.

The third shot put the craft at 240 G. The last thing she saw was the impossible brightness of the reactor as the PMAC’s ferroslug slug hit it dead center. She could feel something wet dripping down her cheeks and she wasn’t sure if it was blood, tears, or vitreous fluid. ---

Aggral Thrawn had been expecting the ship to fire, but he hadn’t expected it to just disappear like that. The heat signatures on the craft were simple enough to track, but the visual contact couldn’t have been amputated more viciously with a chainsaw. As his sensors struggled to reestablish ping with the leviathan he was already barking orders to his fighters, telling them to avoid clustering and to maintain the spherical shell to prevent more than one craft at a time from being targeted.

He took a breath from his orders and glanced at the HUD. Ping had been reestablished, but the reason it had been lost in the first place was apparent. No ship that large should be capable of accelerating that fast. In the two seconds it had been gone it had moved up to almost 2.5 km/s.

A second burst of a radio static signalled the EMP of a second shot, and the ship’s velocity skyrocketed again. His sensors were reporting that the craft was experiencing close to 200 G now. He was frankly surprised that anyone aboard was awake for fire a second shot, the acceleration from the first would’ve crushed his ship, least of all his skeleton.

A third shot followed the second one scant seconds later, the beast far beyond the enclosing sphere of fighters. The strategy struck him too late, but there was no feeling of foolishness this time. No one could’ve predicted this. Nothing like this had been attempted before.

The railgun’s third slug wasn’t simply fired into the void, it struck the ejected fusion reactor, the immense speed of the bullet compressing the volatile deuterium-tritium mixture into a supercritical state. The radiation pressure alone consumed the reactor room, every element larger than iron shattering in a fission chain, every element smaller welding itself to its cousins, the new elements formed continuing the samsaric cycle of death and rebirth.

The incandescent sphere of energy only took a few fractions of a second to consume the entire swarm, their iridium frames sparking new atomic reactions.

He was more than far enough away to survive the explosion, the several thousand kilometers between him and the swarm enough to drive the energy flux from tens of million of watts per meter to a “mere” nine hundred. If his ship hadn’t been built for atmospheric reentry, it would’ve been fried, but luck was carrying him through the day more than skill ever could.

His sensors, on the other hand, didn’t stand a chance. Comms would be the only things that would survive this, and only because they were housed in the hull. As it stood, they’d be useless for the foreseeable future, whatever paltry signals they could produce being drowned out by the primal scream of matter trapped in alternating pulses of fusion and fission, creation and destruction.

The most he could do was watch. The craft he’d been commanding was meant for him alone, and with no crew to peer over his shoulder, he felt no pretend he wasn’t impressed. The bloodpact wasn’t going to spare his life. He may have survived the blast, but he didn’t know how he was going to survive the week. This roiling wave of heat and light might be the last beautiful thing he’d see, and he wasn’t going to pass it up.

Long minutes passed, the inferno of the blast calming itself into quiet embers, the bright whites and blues of thermal emissions and Cherenkov radiation fading into gentle reds from stray flecks of molten slag drifting through the void.

His show was done.

He felt numb. The silence of the cabin seemed oppressive to him now, smothering even. He clicked the comm line on, even the static of blank space preferable to the silence of his thoughts.

Yet it wasn’t silence that blared through his cabin.

“-we are badly injured. The entire sensor array is fried, and the capacitor bank is not meant for long term usage. If there are any ships in the region, please, follow the signal to its source. The USSN will reward you greatly for our safe return, but we need help fast. If anyone is there, please, make your way to the distress beacon.”

His fingers traced over the scar that crossed his fat abdomen, the memento mori that his old captain had engraved into him with the head of an axe. It was a habit of his to do this when he was making a decision. It kept him grounded, reminded him that his actions carried heavy consequences.

His hands stopped their journey, signaling that he'd reached his conclusion. The comm triangulation was primitive compared to just about any other sensor, but his toolbelt was fairly depleted at the moment.

Carefully, he began piloting his craft towards the source of the broadcast.

That isn't a ship, it's a cannon with FTL

Aggral Thrawn’s gut was a grotesque thing to behold: Soft and distended, covered with a coarse layering of fur, a fat purple worm of a scar crossing over it’s almost spherical circumference. So vicious was the scar that even gazing upon it brought unwanted imagery of the fat ape-like creature screaming in pain, both arms working as a dam to keep the tidal wave of bloody guts from spilling out of its three-fingered fists

Yet, for all its grotesque horror, he trusted it. That same gut that had almost gotten him killed so many years before had worked hard to save him again and again after. It was what had brought him from mere gangpress, to quartermaster, all the way to the captain of his own pirate vessel.

And right now, it was telling him to call off the attack. The readings he was getting from the craft ahead made no sense. The crew space was too small, the energy readings were off the charts, and there was something almost military about it. Yet, as he looked over the hull, he couldn’t spot a single weapon. Nothing about it made sense.

The crew had enough in the larders to pass on a ship this sturdy. Even as ships on either side of him pulled forward, eager to be the first to raid the craft, he aborted the ram sequence to watch from a distance.

The crew was disappointed. It’d been too long since they’d had a good, solid fight, but they knew better than to second guess Aggral’s gut. It had earned its place as the ship’s oracle by rite of blood, and was to be respected accordingly.

---

There were only four crew aboard the USSN PMAC: Dalton Dial, in charge of weapon systems, Elizabeth Harris, in charge of navigation, and the Pratchett siblings, who worked together to keep the fifth generation fusion reactor that powered the whole abomination within some semblance of working order.

The Pratchett siblings’ love of the reactor (which they had affectionately named “Sun-Son”) was rivaled only by their hatred of the rest of the craft. Elizabeth and Dalton had more mixed feelings on the matter. Elizabeth considered the ship “Perhaps a little ridiculous on paper, but a work of military genius,” while Dalton lauded the idea as “Literally the coming of the Messiah, the only thing I prayed for my whole adulthood, and the answer to that prayer manifest, just for me, to bring me back to the flock.”

Their mixed feelings could be explained away just by describing the craft concept:

The PMAC was not a ship. It was the largest possible gun that could still be attached to an Alcubierre drive, with just enough manpower to steer, aim, and maintain the thing for long term patrols.

The prototype MAC that the life-support, thrusters, and reactor had been constructed around hadn’t even been built with space in mind. It was originally designed as a ground-to-orbit defense weapon. If it wasn’t for the capacitor bank the ship would’ve needed almost a minute between each shot to get enough power, even with the fifth generation reactor. Luckily, it could start out each battle with enough charge to fire off a salvo of four before needing to begin recharging for its next launch.

It had just such a salvo prepared for the pirate ambush that their military grade scanners had picked up minutes earlier.

Dalton was not taking the delay very well.

“With all due respect mam, I’ve had a lock on all three for almost a minute now. I could just fire and claim that I sneezed. The Pratchetts would back me up on this. Right guys?”

Emily Pratchett snorted.

“Why is it that when the weaponsmaster says ‘with all due respect’ he always means ‘fuck you for giving my stupidly giant gun blue balls?”

Thom Pratchett shrugged.

“Maybe he’d say it less if you weren’t so eager to translate it to the navigator for him.”

Elizabeth was slightly amused by the conversation. It was hard to keep things particularly formal while on a crew this small. Still, she was waiting for something. She’d gotten permission from the brass to take a new approach to fighting with the ship.

They’d proven it could win battles. Now, it was time to establish shock and awe. And as it currently stood, dead men told no tales.

Thus, they needed more living ones. And as she watched two pirate ships pull forward, with one hanging back, she knew just who’d live to pass on this particular legend. ---

Aggral watched the ships advance on his HUD, the blips crossing the thousands of kilometers between them and the strange ship in seconds. For a moment he felt regret. Was he making a mistake? Was this going to be what led to some upstart in the crew thinking they could do things better than him?

Then, the world went mad.

The power readings on the strange ship spiked. Hard. He’d thought that the baseline levels were outrageous, but they must’ve had some sort of absurd capacitor bank to expel that much energy that fast. The twin prongs that made up most of the length of the ship gave off some sort of EMP that fried the electronics of the Viscera, his sister ship, cutting off their radio traffic. His crew scrambled to find some way to regain contact when Gods of the Dead, forgive me my sins, and and forget me my debts, the actual weapon went off. The EMP hadn’t even been the attack, it had just been a side effect.

He hadn’t seen a weapon because he’d been looking for one on the hull, some kind of guardian laser, or a missile pod. He hadn’t even conceived that the whole goddamn vehicle could be the weapon. But what kind of weapon would charge up like that? A laser would just fire over a sustained period. What would need a burst like-

He stopped midthought as it hit him: A railgun.

He stopped again as it hit them: The kinetic charge would have to have been moving at almost 0.8c for it to just ignore the evasive maneuvers like that. The ferroslug itself wasn’t detected by any of their defense measures aboard, but the thermal readings of the Viscera made every infared sensor aboard scream in horror. Contact with whatever slug had hit it must’ve reduced the whole thing to plasma. It was almost inconceivable.

He was already screaming out the full retreat call when the ship fired twice in rapid succession at the Rictus, which was still recovering from what had just happened to its partner. The first shot was dead through the center. The second hit some target a few dozen meters off to the side.

A direct hit on an escape pod. Apparently, the captain had tried to save himself. Even in the mortal terror that he felt at that moment, Aggral could take a grim satisfaction at that second shot. To leave all the men that followed you to their deaths was a cowardice that he could not bear to consider. He would rather die.

And now, he was going to. Jump was fifteen seconds away, and the console was telling him that the ship was pinged. They knew where he was, they had him in their crosshairs, and they were going to pull the trigger.

He traced a finger over the purple scar absentmindedly. This was it. He’d been living on borrowed time since that first wound, and now he was to meet his ancestors.

He was ready.

---

Dalton was wincing, even as he maintained his ping on the ship. He knew that Elizabeth was just doing her job, but even by his admittedly bloodthirsty standards, there was something fucked up about keeping a ship in ping like this. It was like forcing someone to look you in the eyes before you slit their throat. Way too personal for his tastes.

Elizabeth was keeping an eye on the craft, making sure that no escape pods were jettisoning. Part of her was hoping that some would, but whatever other faults these pirates had, they were loyal to each other at least. As the ultraviolet scanners gave the telltale flair of redshift, she told Dalton to turn off the ping.

To say he was relieved was an understatement. In the middle of a firefight, he couldn’t question Elizabeth’s orders, but for the first time in a long time, he’d been afraid to pull the trigger. Now he didn’t have to.

He almost slid out of his chair as he asked the question that had been on his mind since the engagement began.

“Mam, what the hell was that?”

Elizabeth smiled warmly at her very surprised crew even as her words came out, cold as ice.

“A message.”

---

Thanks for reading this far! I'm moving my previous works from reddit to here. If you follow me, more will come. If you're impatient, you can skip to the source and read things at https://www.reddit.com/user/InBabylonTheyWept/

462 notes

·

View notes

Text

USAF Special Operations Command receives the latest AC-130J Ghostrider

Fernando Valduga By Fernando Valduga 11/04/2022 - 14:00 in Military

An AC-130J Ghostrider taxis on the flight line after the delivery and dedication ceremony of the AC-130J Ghostrider, on November 2, 2022, at Bob Sikes Airport in Crestview, Florida. (Photo: US Air Force)

The U.S. Air Force Special Operations Command (USSOCOM) received its 31st and final AC-130J Ghostrider, completing the transition of the command of the AC-130W, AC-130U and AC-130H fleets.

After a celebration ceremony at the Lockheed Martin Gunship Modification Facility in Crestview on November 2, the final AC-130J was delivered to the 27th Special Operations Wing at Cannon Air Base, New Mexico.

During the delivery and dedication ceremony of AC-130J Ghostrider, Lieutenant Colonel Joe Allen, Gunship program manager and narrator of the event, briefly discussed the history of nose art and how it became a common way of representing the name of an airplane. He also explained how pilots would write names or call signals on their aircraft, providing a sense of connection and a feeling of pride for themselves and the crew that kept the plane flying.

"The aircraft No. 31 is no different [of the previous aircraft of World War II] and is being named after Mr. Stan 'Sluggo' Siefke, who was instrumental in the development of the precision attack package before cutting the first metal in the MC-130W," Allan said. "The Sluggo impacts on Whisky and Ghostrider were none other than excellent and we are honored to have it present today."

The AC-130J is the fifth-generation attack aircraft that replaces the fleet of AC-130U Spooky and AC-130W Stinger II aircraft. The AC-130 'gunships' have an extensive history of combat dating back to Vietnam, where the fighters destroyed more than 10,000 trucks and were credited with many missions of approximate air support and lifeguards.

USSOCOM is developing the AC-130J through the integration of modular components in existing MC-130J aircraft. Modular components include a dual console mission operator (MOP) pallet in the cargo compartment that controls all subsystems with remote displays and control panels in the control cabin; 30 mm side-shot chain rotary cannon mounted on a pallet and 105 mm cannon; GBU-39/B GPS-guided small-B GPS-mounted pumps and AGM-176 Griffin laser-guided missiles. The command also plans to equip the Ghostriders with targeted energy weapons systems or lasers, as they are most commonly known.

Lieutenant General Jim Slife, commander of the AFSOC, represented the command at the ceremony and talked about his experience with the acquisition and receipt of the AC-130J, remembering that it was only a few years ago when he was then colonel, working at the Pentagon for the Office of the Secretary of Defense, began the message and the formative language that started the program he is seeing closing

“In the fall of 2009, the secretary of defense decided to recapitalize [the AC-130] with C-130Js to build the platforms we see behind us today,” Slife said.

He also talked about seeing the first J model go into combat in the summer of 2019 while serving as AFSOC commander.

“The plane and its predecessors exceeded all our expectations and kept more Americans alive than any other plane on the battlefield,” Slife said.

"The future will be different from what we have experienced in the last 20 years, but one thing I'm sure is that this plane will be relevant to whatever the future operational environment will bring, so thank you all for delivering such a magnificent aircraft with capacity for today's fighters," he said.

Captain Katie Tiedemann, weapons systems officer of the 73rd Special Operations Squadron, shared AC-130J operational vignettes during the event. She specifically shared her own experience in Afghanistan when she supported Operation Allies Refuge.

"For two weeks, my own crew and two others continued to employ our aircraft for countless ?? hours, reopening the airport [of Kabul] and evacuating 123,000 refugees," Tiedemann said. "Most of the rest of the story you have seen and heard, but our two crews who flew during the evacuation will be recognized this fall with the MacKay trophy for making the most meritorious flight of the year."

After the presentation of Captain Tiedemann, William Innes, deputy director of acquisition, United States Special Operations Command, spoke about the part of USSOCOM in navigating the acquisition process to take the industry's weapons systems to the fighter.

"When we can see firsthand that [the acquisition process] works, it delivers the best weapon system that the nation can get, it's really inspiring," he said.

Vic Torla, vice president of the Global Logistics Support Services of the Special Operations Forces at Lockheed Martin, expressed his gratitude for the partnership between Lockheed Martin and the U.S. Air Force.

“A great example of a partnership between government and industry to maintain this facility,” Torla said. "A ten-year journey to deliver what are now 30 aircraft with combat capability to the Special Operations Command".

At the conclusion of the ceremony, Slife, along with the crew, stepped on the new AC-130J and took off to Cannon Air Base, where the final AC-130J will be part of the 27th Special Operations Wing.

The AFSOC received its final Ghostrider the same week that the U.S. Marine Corps received its final attack helicopter AH-1Z Viper, completing the registration H-1 program.

Tags: Military AviationLockheed Martin AC-130J GhostriderSOCOM - Special Operations CommandUSAF - United States Air Force / US Air Force

Previous news

9 reasons why the F-35 needs a new engine

Next news

Russia claims that the United Kingdom is involved in a drone attack on three Black Sea warships

Fernando Valduga

Fernando Valduga